Home > Press > LayTec to develop in-situ sensor for ISE’s triple-junction PV cells

|

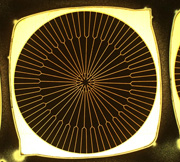

| Multi-junction concentrator solar cell with an efficiency of 39.7% at a concentration factor of 300, developed at Fraunhofer ISE. |

Abstract:

LayTec GmbH of Berlin, Germany says that the German Federal Ministry of Economics and Technology (Bundesministerium für Wirtschaft und Technologie) has approved funding within the PRO Inno Program for the development of a new in-situ sensor for the photovoltaic market.

LayTec to develop in-situ sensor for ISE’s triple-junction PV cells

Berlin, Germany | Posted on October 6th, 2008 In collaboration with the Fraunhofer Institute for Solar Energy Systems (ISE) in Freiburg, Germany, a research project has been launched to improve the in-situ monitoring of MOCVD processes for triple-junction photovoltaic cells being developed at Fraunhofer ISE (which recently set the European record for solar cell efficiency, at 39.7%). Cooperation between LayTec and ISE's III-V Epitaxy and Solar Cells group is aimed at developing monitoring sensors for industrial-scale manufacturing of triple-junction solar cells with improved process control in multi-wafer MOCVD reactors. "Real-time analysis and control of our processes is becoming a key for the development of complex semiconductor structures such as multi-junction solar cells" says Dr Frank Dimroth, head of ISE's III-V Epitaxy and Solar Cells group.

ISE's cells are the most efficient produced in Europe. ISE transfers its process technology to the cooperation partner Azur Space Solar Power GmbH of Heilbronn, Germany (Azur SSP), which prepares them for commercial production. ISE and Azur SSP use Aixtron Planetary systems for both development and manufacturing. LayTec's EpiCurveTT sensor, which the firm claims is already the bestseller for the MOCVD LED market, will be further improved to achieve the resolution necessary for multi-junction solar cell growth under the conditions of planetary rotation. In addition to temperature, layer thickness and strain measurements, the new sensor aims to determine the composition and help to better understand the reasons for dislocations and strain within the layers. This will help to compensate for strain-induced temperature inhomogeneities, to determine the thickness of individual thin layers and to monitor the composition of critical heterojunctions, says LayTec.

*LayTec has recruited Dr Qi Cao as a sales engineer. After graduating in physics from China's Nanjing University of Science and Technology, Cao undertook research on optical features of nano-structure materials and obtained a PhD in Optical Engineering in 2004, before continuing research on laser transmission characteristics of nano-holes at Germany's Konstanz University and finally focusing on opto-electric features of single molecules at Münster University. Since 2006, she has gained experience in sales and customer support working for Olympus Microscope in the USA.

At LayTec, Cao will be in charge of sales activities mainly in Taiwan and Greater China, and will support customers and distributors worldwide.

####

About LayTec GmbH

LayTec GmbH was founded in 1999 after an initial period of scientific research and development at the Technical University of Berlin. The company was able to draw from a diverse range of scientific knowledge, patents and entrepreneurial experience in the semiconductor industry to position itself as an innovator and dominant brand in the real-time thin-film optical sensor market.

For more information, please click here

Contacts:

Helmholtzstr. 13/14

D-10587 Berlin

Germany

Tel: +49 (0)30 39 800 80-0

Fax:+49 (0)30 39 800 80-80

Copyright © LayTec GmbH

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related News Press |

News and information

![]() Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

![]() Good as gold - improving infectious disease testing with gold nanoparticles April 5th, 2024

Good as gold - improving infectious disease testing with gold nanoparticles April 5th, 2024

Thin films

![]() Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

![]() Understanding the mechanism of non-uniform formation of diamond film on tools: Paving the way to a dry process with less environmental impact March 24th, 2023

Understanding the mechanism of non-uniform formation of diamond film on tools: Paving the way to a dry process with less environmental impact March 24th, 2023

![]() New study introduces the best graphite films: The work by Distinguished Professor Feng Ding at UNIST has been published in the October 2022 issue of Nature Nanotechnology November 4th, 2022

New study introduces the best graphite films: The work by Distinguished Professor Feng Ding at UNIST has been published in the October 2022 issue of Nature Nanotechnology November 4th, 2022

Govt.-Legislation/Regulation/Funding/Policy

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

![]() Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

Sensors

Announcements

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Solar/Photovoltaic

![]() Development of zinc oxide nanopagoda array photoelectrode: photoelectrochemical water-splitting hydrogen production January 12th, 2024

Development of zinc oxide nanopagoda array photoelectrode: photoelectrochemical water-splitting hydrogen production January 12th, 2024

![]() Shedding light on unique conduction mechanisms in a new type of perovskite oxide November 17th, 2023

Shedding light on unique conduction mechanisms in a new type of perovskite oxide November 17th, 2023

![]() Inverted perovskite solar cell breaks 25% efficiency record: Researchers improve cell efficiency using a combination of molecules to address different November 17th, 2023

Inverted perovskite solar cell breaks 25% efficiency record: Researchers improve cell efficiency using a combination of molecules to address different November 17th, 2023

![]() Charged “molecular beasts” the basis for new compounds: Researchers at Leipzig University use “aggressive” fragments of molecular ions for chemical synthesis November 3rd, 2023

Charged “molecular beasts” the basis for new compounds: Researchers at Leipzig University use “aggressive” fragments of molecular ions for chemical synthesis November 3rd, 2023

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||