Home > Press > From Sugar to Gasoline

|

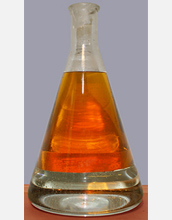

| The physical properties of Virent's Biogasoline product spontaneously separate from water. This requires very little energy for processing compared with the energy-intensive process of distillation required for ethanol purification.

Credit: Virent Energy Systems, Inc. Contact Virent for image permissions and use. |

Abstract:

Using processes familiar to the petroleum industry, two separate research groups craft "green gasoline" from sugar and carbohydrates

From Sugar to Gasoline

Arlington, VA | Posted on September 18th, 2008Following independent paths of investigation, two research teams are announcing this month that they have successfully converted sugar-potentially derived from agricultural waste and non-food plants-into gasoline, diesel, jet fuel and a range of other valuable chemicals.

Chemical engineer Randy Cortright and his colleagues at Virent Energy Systems of Madison, Wisc., a National Science Foundation (NSF) Small Business Innovation Research awardee, and researchers led by NSF-supported chemical engineer James Dumesic of the University of Wisconsin at Madison are now announcing that sugars and carbohydrates can be processed like petroleum into the full suite of products that drive the fuel, pharmaceutical and chemical industries.

"NSF and other federal funding agencies are advocating the new paradigm of next generation hydrocarbon biofuels," said John Regalbuto, director of the Catalysis and Biocatalysis Program at NSF and chair of an interagency working group on biomass conversion. "Even when solar and wind, in addition to clean coal and nuclear, become highly developed, and cars become electric or plug-in hybrid, we will still need high energy-density gasoline, diesel and jet fuel for planes, trains, trucks, and boats. The processes that these teams developed are superb examples of pathways that will enable the sustainable production of these fuels."

The process Virent discovered in early 2006, and announced at the Growing the Bioeconomy conference sponsored by Iowa State University on Sept. 9, 2008, is the subject of patent applications published last week.

That announcement was followed this month by the publication of a separate discovery of the same process in the Dumesic laboratory. Dumesic and his colleagues announce their findings in the Sept. 18, 2008 online ScienceExpress, to be followed in print in the Oct. 18, 2008, issue of Science.

The key to the breakthrough is a process developed by both Dumesic and Cortright called aqueous phase reforming. In passing a watery slurry of plant-derived sugar and carbohydrates over a series of catalysts-materials that speed up reactions without sacrificing themselves in the process-carbon-rich organic molecules split apart into component elements that recombine to form many of the chemicals that are extracted from non-renewable petroleum.

According to Dumesic, a key feature of the approach is that between the sugar or starch starter materials and the hydrocarbon end products, the chemicals go through an intermediate stage as an organic liquid composed of functional compounds.

"The intermediate compounds retain 95 percent of the energy of the biomass but only about 40 percent of the mass, and can be upgraded into different types of transportation fuels, such as gasoline, jet and diesel fuels," said Dumesic. "Importantly, the formation of this functional intermediate oil does not require the need for an external source of hydrogen," he added, since hydrogen comes from the slurry itself.

As part of a suite of second generation biofuel alternatives, green gasoline approaches like aqueous phase reforming are generating interest across the academic and industrial communities because they yield a product that is compatible with existing infrastructure, closer than many other alternatives in their net energy yield, and most importantly, can be crafted from plants grown in marginal soils, like switchgrass, or from agricultural waste.

While several years of further development will be needed to refine the process and scale it for production, the promise of gasoline and other petrochemicals from renewable plants has led to broad industrial interest.

Virent's process, called BioForming, is allowing the company to address one of the key goals of NSF's SBIR program, commercialization, and a broader NSF target, American competitiveness. A recent alliance with one of the world's largest energy companies aims to bring these alternative fuels to market, and investment from major automotive and agricultural companies from around the world are broadening the company's impact.

"The early support of NSF helped lay the groundwork for our technical, and subsequent industrial, successes," said Cortright, chief technology officer at Virent. "Our scientists now have years of expertise with our BioForming process and are rapidly moving the technology to commercial scale. We are quickly working to put our renewable, green gasoline and other hydrocarbon biofuels in fuel tanks all over the world."

Added Rose Wesson, the NSF program officer who oversaw Virent's grant, "The technology developed by Virent is extremely promising, and has been refined over the last six years. The aqueous phase reforming process used by both research is an innovative approach that may yield an important, positive impact on the energy demands of the U.S. and worldwide."

On Sept. 23, 2008, at 2:00 p.m., three leading experts from academia and industry, including Randy Cortright and George Huber, both former students of Jim Dumesic, will host a panel discussion at NSF to highlight how far researchers have come, and how far they still need to go, to bring plant-derived gasoline to market. For additional information, see the media advisory at: nsf.gov/news/news_summ.jsp?cntn_id=112243.

####

About National Science Foundation

The National Science Foundation (NSF) is an independent federal agency that supports fundamental research and education across all fields of science and engineering, with an annual budget of $6.06 billion. NSF funds reach all 50 states through grants to over 1,900 universities and institutions. Each year, NSF receives about 45,000 competitive requests for funding, and makes over 11,500 new funding awards. NSF also awards over $400 million in professional and service contracts yearly.

For more information, please click here

Contacts:

Media Contacts

Joshua A. Chamot

NSF

(703) 292-7730

Madeline Fisher

University of Wisconsin-Madison

(608) 890-0465

Mary Blanchard

Virent Energy Systems, Inc.

(608) 237 8615

Program Contacts

John Regalbuto

NSF

(703) 292-7047

Rosemarie D. Wesson

NSF

(703) 292-7070

Principal Investigators

James Dumesic

University of Wisconsin-Madison

(608) 262-1095

Randy Cortright

Virent Energy Systems, Inc.

(608) 663-0228

Copyright © National Science Foundation

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related News Press |

News and information

![]() Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Videos/Movies

![]() New X-ray imaging technique to study the transient phases of quantum materials December 29th, 2022

New X-ray imaging technique to study the transient phases of quantum materials December 29th, 2022

![]() Solvent study solves solar cell durability puzzle: Rice-led project could make perovskite cells ready for prime time September 23rd, 2022

Solvent study solves solar cell durability puzzle: Rice-led project could make perovskite cells ready for prime time September 23rd, 2022

![]() Scientists prepare for the world’s smallest race: Nanocar Race II March 18th, 2022

Scientists prepare for the world’s smallest race: Nanocar Race II March 18th, 2022

![]() Visualizing the invisible: New fluorescent DNA label reveals nanoscopic cancer features March 4th, 2022

Visualizing the invisible: New fluorescent DNA label reveals nanoscopic cancer features March 4th, 2022

Govt.-Legislation/Regulation/Funding/Policy

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

![]() Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

Announcements

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Energy

![]() Development of zinc oxide nanopagoda array photoelectrode: photoelectrochemical water-splitting hydrogen production January 12th, 2024

Development of zinc oxide nanopagoda array photoelectrode: photoelectrochemical water-splitting hydrogen production January 12th, 2024

![]() Shedding light on unique conduction mechanisms in a new type of perovskite oxide November 17th, 2023

Shedding light on unique conduction mechanisms in a new type of perovskite oxide November 17th, 2023

![]() Inverted perovskite solar cell breaks 25% efficiency record: Researchers improve cell efficiency using a combination of molecules to address different November 17th, 2023

Inverted perovskite solar cell breaks 25% efficiency record: Researchers improve cell efficiency using a combination of molecules to address different November 17th, 2023

![]() The efficient perovskite cells with a structured anti-reflective layer – another step towards commercialization on a wider scale October 6th, 2023

The efficient perovskite cells with a structured anti-reflective layer – another step towards commercialization on a wider scale October 6th, 2023

Events/Classes

![]() Researchers demonstrate co-propagation of quantum and classical signals: Study shows that quantum encryption can be implemented in existing fiber networks January 20th, 2023

Researchers demonstrate co-propagation of quantum and classical signals: Study shows that quantum encryption can be implemented in existing fiber networks January 20th, 2023

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||