Home > Press > 'Nanonet' circuits closer to making flexible electronics reality

|

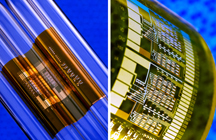

| These are two photos of flexible circuits created using carbon nanotubes in research at Purdue University and the University of Illinois at Urbana-Champaign. The researchers have overcome a major obstacle in producing transistors from networks of carbon nanotubes, a technology that could make it possible to print circuits on plastic sheets for applications including flexible displays and an electronic skin to cover an entire aircraft to monitor crack formation. (University of Illinois at Urbana-Champaign) |

Abstract:

Medium Scale Carbon Nanotube Thin Film Integrated Circuits on Flexible Plastic Substrates

Qing Cao1, Hoon-sik Kim2, Ninad Pimparkar7, Jaydeep P. Kulkarni7, Congjun Wang2, Moonsub Shim2, Kaushik Roy7, Muhammad A. Alam7, John A. Rogers 1-6

1Department of Chemistry, 2Department of Materials Science and Engineering

3Department of Electrical and Computer Engineering, 4Department of Mechanical Science and Engineering,5 Frederick-Seitz Materials Research Laboratory, 6Beckman Institute for Advanced Science and Technology, University of Illinois at Urbana-Champaign

7School of Electrical and Computer Engineering, Purdue University

The ability to form integrated circuits (ICs) on flexible sheets of plastic enables attributes in electronic devices that are difficult or impossible to achieve with technologies that use semiconductor wafers or glass plates as substrates. Organic small molecule and polymer-based materials represent the most widely explored types of semiconductors for such flexible ICs. Although these materials and those that use films or nanostructures of inorganics have promise for certain applications, existing demonstrations of them in ICs on plastic indicate modest performance characteristics that might restrict the application possibilities. Here, we report advanced implementations of a comparatively high-performance carbon-based semiconductor consisting of sub-monolayer, random networks of single-walled carbon nanotubes (SWNTs) to yield small- to medium-scale, integrated digital circuits, including inverters, NOR and NAND logic gates, and four bit row decoders with nearly one-hundred transistors on thin plastic substrates, all with excellent electrical and mechanical properties. Optimized layouts of the SWNTs in these networks, combined with low-resistance contacts and ultrahigh capacitance, hysteresis-free gate dielectrics yield transistors in these ICs that have attractive properties: mobilities as high as 80 cm2/Vs, subthreshold slopes as low as 160 mV/dec, operating voltages <5 V together with deterministic control over the threshold voltages, on/off ratios as high as 105, switching speeds well in the kHz range even for coarse (~100 mm) device geometries and good mechanical bendability, all with levels of uniformity and reproducibility that enable high yield fabrication of ICs. Theoretical calculations, ranging from percolation transport through the networks to compact models for the transistors to circuit level simulations of the various logic gates, provide quantitative and predictive understanding of these systems. Taken together, these results suggest that sub-monolayer films of SWNTs represent an attractive type of carbon-based semiconductor for flexible ICs, with many potential areas of application in consumer and other areas of electronics.

'Nanonet' circuits closer to making flexible electronics reality

WEST LAFAYETTE, IN | Posted on July 23rd, 2008Researchers have overcome a major obstacle in producing transistors from networks of carbon nanotubes, a technology that could make it possible to print circuits on plastic sheets for applications including flexible displays and an electronic skin to cover an entire aircraft to monitor crack formation.

The so-called "nanonet" technology - circuits made of numerous carbon nanotubes randomly overlapping in a fishnet-like structure - has been plagued by a critical flaw: The network is contaminated with metallic nanotubes that cause short circuits.

The discovery solves this problem by cutting the nanonet into strips, preventing short circuits by breaking the path of metallic nanotubes.

"This is a fundamental advance in how nanotube circuits are made," said Ashraf Alam, a professor of electrical and computer engineering at Purdue University. He is working with Kaushik Roy, Purdue's Roscoe H. George Professor of Electrical and Computer Engineering, and doctoral students Ninad Pimparkar and Jaydeep P. Kulkarni.

Researchers at the University of Illinois at Urbana-Champaign led experimental laboratory research to build the circuits, and Purdue led research to develop and use simulations and mathematical models needed to design the circuits and to interpret and analyze data.

Findings will be detailed in a research paper appearing in the journal Nature on July 24. The paper was written by the Purdue engineers and University of Illinois researchers : John A. Rogers, Founder Professor of Materials Science and Engineering and a professor of chemistry; Moonsub Shim, Racheff Assistant Professor of Materials Science and Engineering; and doctoral students Qing Cao, Hoon-sik Kim and Congjun Wang.

"These findings represent the culmination of four years of collaborative efforts between the Illinois and Purdue groups," Rogers said. "The work established the fundamental scientific knowledge that led to this particular breakthrough and the ability to make circuits."

The nanonets are made of tiny semiconducting cylinders called single walled carbon nanotubes. Metallic nanotubes form unavoidably during the process of making carbon nanotubes. These metal tubes then link together in meandering threads that eventually stretch across the width of the transistor, causing a short circuit.

"Other researchers have proposed eliminating the metallic nanotubes," Rogers said. "Instead, we found a very nice way of essentially removing the effect of these metallic nanotubes without actually eliminating them."

The researchers created a flexible circuit containing more than 100 transistors, the largest nanonet ever produced and the first demonstration of a working nanonet circuit, Alam said.

"Now there is no fundamental reason why we couldn't develop nanonet technologies," he said. "If you can make a flexible circuit with 100 transistors, you can make circuits with 10,000 or more transistors."

The advance may allow researchers to use carbon nanotube transistors to create high-performance, shock-resistant, lightweight and flexible integrated circuits at low cost, Alam said.

A key advantage of the nanonet technology is that it can be produced at low temperatures, enabling the transistors to be placed on flexible plastic sheets that would melt under the high temperatures required to manufacture silicon-based transistors, he said.

Possible applications include an electronic skin that covers an aircraft and automatically monitors the formation of cracks to alert technicians and prevent catastrophic failures.

Such shape-conforming electronics are not possible using conventional silicon-based circuits, which are manufactured on rigid wafers or glass plates.

"Now electronics are flat, which limits their utility since most objects in real life are not flat," Roy said.

Flexible displays could be integrated into automotive windshields to provide information for drivers. Other potential applications include "electronic paper" that displays text and images, solar cells that could be printed on plastic sheets and television screens capable of being rolled up for transport and storage.

"For these types of applications, manufacturers might literally print, or stamp, circuits onto plastic sheets, like the roll-to-roll printing used to print newspapers," Alam said.

Conventional circuits for flat-panel televisions contain transistors made of materials called polysilicon or amorphous silicon, which cannot be used in flexible applications.

Nanonet transistors are promising for so-called macroelectronics because they are best suited for large-scale applications, but these transistors may not be as well suited for the requirements of microelectronic circuits, such as those in computer chips, Alam said.

The nanotubes are arranged randomly and overlap each other like tiny needles. If the nanonet area is large enough, the overlapping metallic nanotubes will eventually form a meandering string across the entire transistor, causing a short circuit. But if the device is segmented into strips, this meandering path of metallic rods is cut at the point where the lines separate one strip from another, preventing short circuits.

The metallic nanotubes make up about one-third of the nanotubes in the transistor. Because the carbon nanotubes are twice as numerous as the metallic tubes, enough of them exist to form a complete circuit. The models and simulations are needed to tell researchers precisely how wide to make the strips so that the pathway of metallic tubes is cut but the carbon nanotubes complete their circuit.

"The theory and simulation work done at Purdue shows there is always a way to break the metallic path and still keep the semi conducting carbon-nanotube path intact," Alam said. "The teams at Illinois and Purdue continuously provide insights about why things work the way they do and how to make them work better through combined modeling and experimental efforts."

Each nanonet transistor consists of numerous strips of nanotubes, separated bylines that are etched in place. The lines are easy to create with a standard etching process used in the semiconductor industry.

Future research may include work focusing on learning the reliability of the carbon nanotube circuits.

The research has been funded by the National Science Foundation through the Network for Computational Nanotechnology at the Birck Nanotechnology Center in Purdue's Discovery Park. The Illinois portion of the research also was funded and supported by the NSF, U.S. Department of Energy, Motorola Corp., and by the university's Frederick Seitz Materials Research Lab, the Center for Microanalysis of Materials and the Department of Chemistry.

The researchers used computers made available by a global network called the nanoHUB, an Internet-based science gateway that provides computer-based resources for research and education in the areas of nanoelectronics and nanoelectromechanical systems and their application to nano-biosystems.

"This work requires tremendous computing resources because these are not trivial calculations," Alam said.

Nanoelectronics focuses on creating a class of electronic devices containing features measured in nanometers, equivalent to one-billionth of a meter. A nanometer is about the size of 10 atoms strung together.

The Network for Computational Nanotechnology uses advanced theory and simulations to explore new ideas for digital switching devices such as innovative types of transistors that promise to help researchers create future electronics.

The research is complementary to work by Purdue researcher David Janes, a professor of electrical and computer engineering. His work involves transparent circuits using a different type device called nanowires, made of indium oxide instead of carbon nanotubes.

####

About Purdue University

Note to Journalists: Journalists may obtain a copy of the research paper by contacting Nature at or calling press officer Katherine Anderson at (212) 726-9231.

For more information, please click here

Contacts:

Writer: Emil Venere

(765) 494-4709

Sources: Ashraf Alam

(765) 494-5988

Kaushik Roy

(765) 494-2361

John Rogers

(217) 244-4979

Purdue News Service:

(765) 494-2096

Copyright © Purdue University

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related News Press |

News and information

![]() Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

![]() Good as gold - improving infectious disease testing with gold nanoparticles April 5th, 2024

Good as gold - improving infectious disease testing with gold nanoparticles April 5th, 2024

Display technology/LEDs/SS Lighting/OLEDs

![]() Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

![]() Light guide plate based on perovskite nanocomposites November 3rd, 2023

Light guide plate based on perovskite nanocomposites November 3rd, 2023

![]() Simple ballpoint pen can write custom LEDs August 11th, 2023

Simple ballpoint pen can write custom LEDs August 11th, 2023

Chip Technology

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

![]() Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

![]() HKUST researchers develop new integration technique for efficient coupling of III-V and silicon February 16th, 2024

HKUST researchers develop new integration technique for efficient coupling of III-V and silicon February 16th, 2024

Nanotubes/Buckyballs/Fullerenes/Nanorods/Nanostrings

![]() Tests find no free-standing nanotubes released from tire tread wear September 8th, 2023

Tests find no free-standing nanotubes released from tire tread wear September 8th, 2023

![]() Detection of bacteria and viruses with fluorescent nanotubes July 21st, 2023

Detection of bacteria and viruses with fluorescent nanotubes July 21st, 2023

Nanoelectronics

![]() Interdisciplinary: Rice team tackles the future of semiconductors Multiferroics could be the key to ultralow-energy computing October 6th, 2023

Interdisciplinary: Rice team tackles the future of semiconductors Multiferroics could be the key to ultralow-energy computing October 6th, 2023

![]() Key element for a scalable quantum computer: Physicists from Forschungszentrum Jülich and RWTH Aachen University demonstrate electron transport on a quantum chip September 23rd, 2022

Key element for a scalable quantum computer: Physicists from Forschungszentrum Jülich and RWTH Aachen University demonstrate electron transport on a quantum chip September 23rd, 2022

![]() Reduced power consumption in semiconductor devices September 23rd, 2022

Reduced power consumption in semiconductor devices September 23rd, 2022

![]() Atomic level deposition to extend Moore’s law and beyond July 15th, 2022

Atomic level deposition to extend Moore’s law and beyond July 15th, 2022

Discoveries

![]() Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

![]() New micromaterial releases nanoparticles that selectively destroy cancer cells April 5th, 2024

New micromaterial releases nanoparticles that selectively destroy cancer cells April 5th, 2024

![]() Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Announcements

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||