Home > Press > Spin Control: New Technique Sorts Nanotubes by Length

|

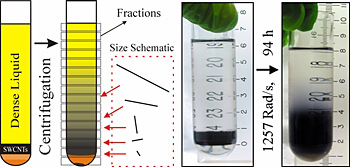

| In a schematic of NIST's length separation technique for carbon nanotubes (l.), the nanotubes start at the bottom of a dense fluid. When spun in a centrifuge, the nanotubes begin to migrate through the fluid driven by their buoyancy, but the longer ones move faster, spreading them out by length. Photos (r.) shows a typical sample at the start and after 94 hours of spinning at 1257 radians per second (roughly 12,000 RPM).

Credit: NIST |

Abstract:

Researchers at the National Institute of Standards and Technology (NIST) have reported* a new technique to sort batches of carbon nanotubes by length using high-speed centrifuges. Many potential applications for carbon nanotubes depend on the lengths of these microscopic cylinders, and one of the most important features of the new technique, say the scientists, is that it should be easily scalable to produce industrial quantities of high-quality nanotubes.

Spin Control: New Technique Sorts Nanotubes by Length

GAITHERSBURG, MD | Posted on May 13th, 2008So-called single wall carbon nanotubes (SWCNTs) are essentially sheets of carbon atoms only one atom thick that have rolled themselves into tubes with a diameter of approximately one nanometer. They have unique combinations of thermal, mechanical, optical and electronic properties that suggest a wide variety of uses, including circuit elements in molecular electronics, fluorescent tags for diagnostic and therapeutic applications in medicine and light sources for compact, efficient flat-panel displays, among many others.

Unfortunately, the methods for manufacturing carbon nanotubes always create a large percentage of nanojunk in the mix—clumps of carbon, ordinary soot, particles of metal used as a catalyst—and nanotubes come in an enormous range of lengths, from a few tens or hundreds, up to thousands of nanometers. Refining the lot is essential for most uses. For many potential applications, nanotubes need to be separated by length. In biomedical applications, for example, it has been shown that whether or not nanotubes are taken up in cells depends critically on length (see "Study: Cells Selectively Absorb Short Nanotubes.") Nanotubes used as components in future microcircuits obviously need to fit in place, and in optical applications, a nanotube's length determines how strongly it will absorb or emit light (see "Longer is Better for Nanotube Optical Properties.")

In 2006, researchers found that you could separate nanotubes by "chirality" (a measure of the twist in the carbon atom sheet) by spinning them in a dense fluid in an ultracentrifuge tube because of a relationship between chirality and buoyancy. In this new work, a team of NIST researchers demonstrated that a variation of the same technique can separate nanotubes by length. They showed that while the nanotubes ultimately will move to a point of equilibrium in the centrifuge tube dictated by their buoyancy, due to friction they will move at different rates depending on their lengths.

"When we spin the centrifuge, it turns out that the longer ones move faster. We basically just run a race and the longer ones move farther in the same amount of time," says researcher Jeffrey Fagan, "Eventually they get separated enough in position that we can just pull off layers and get different lengths."

What's particularly exciting, they say, is that while other techniques have been shown to sort nanotubes by length, this is the first approach that could be scaled up to produce commercially important quantities of nanotubes in a given length range. The process also removes much of unwanted junk—particularly metal particles—from the batch. NIST has applied for a patent on the process.

* J.A. Fagan, M.L. Becker, J. Chun and E.K. Hobbie. Length fractionation of carbon nanotubes using centrifugation. Advanced Materials. 2008. 20. 1609-1613.

####

About NIST

From automated teller machines and atomic clocks to mammograms and semiconductors, innumerable products and services rely in some way on technology, measurement, and standards provided by the National Institute of Standards and Technology.

Founded in 1901, NIST is a non-regulatory federal agency within the U.S. Department of Commerce. NIST's mission is to promote U.S. innovation and industrial competitiveness by advancing measurement science, standards, and technology in ways that enhance economic security and improve our quality of life.

For more information, please click here

Contacts:

Michael Baum

(301) 975-2763

Copyright © NIST

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related News Press |

News and information

![]() Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Nanotubes/Buckyballs/Fullerenes/Nanorods/Nanostrings

![]() Tests find no free-standing nanotubes released from tire tread wear September 8th, 2023

Tests find no free-standing nanotubes released from tire tread wear September 8th, 2023

![]() Detection of bacteria and viruses with fluorescent nanotubes July 21st, 2023

Detection of bacteria and viruses with fluorescent nanotubes July 21st, 2023

Discoveries

![]() Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

![]() New micromaterial releases nanoparticles that selectively destroy cancer cells April 5th, 2024

New micromaterial releases nanoparticles that selectively destroy cancer cells April 5th, 2024

![]() Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Announcements

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||