Home > Press > Tire service life extended

|

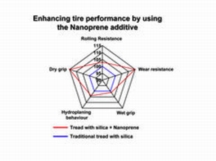

| Summer tire performance has been enhanced by using Nanoprene in the tire tread, significantly reducing wear and thus extending service life. Dry grip has also been considerably improved over traditional tires with comparable wet grip. (Image size: 18 cm x 13 cm / Image author: LANXESS AG / Image utilization: Photo may be reproduced free of charge. "Photo Credit: LANXESS AG" |

Abstract:

Nano additive reduces wear

Tire service life extended

Leverkusen, Germany | Posted on January 17th, 2008Specialty chemicals group LANXESS has developed a new high-performance rubber additive - Nanoprene. This material additive for the rubber mixture of the tire tread significantly cuts wear in automobile tires. The much longer service life of the tire as a wearing part is easy on the wallet and the environment. Unlike with many new developments in the tire rubber sector, use of this additive to enhance wear resistance does not in any way impact on rolling resistance or wet grip.

"Boosting tire service life without losing other key tread properties was a major challenge for the rubber industry," explains Nanoprene developer Prof. Werner Obrecht, rubber expert at the LANXESS Technical Rubber Products (TRP) business unit. "Despite all the positive developments of the last 20 years, after traveling around 40,000 kilometers, the tread pattern is normally worn and new tires are then needed. This is not only annoying for the customer, since the fine rubber particles created by the tire wear ultimately end up in the environment." The wear properties of a tire rubber are linked to its wet grip and rolling resistance through the "magic triangle of tire technology." To put it simply, it is not possible to have everything at once, i.e. low fuel consumption, reliability on dry and wet roads and a tire that lasts forever. If improvement is desired for one of these properties, this is not feasible without making concessions on the others.

Nanoprene reduces this conflict of objectives. In chemical terms, this additive consists of particles of only around 50 nanometers made from polymerized styrene and butadiene - i.e. "traditional" tire rubber raw materials. What makes all the difference is the minimal size and surface functionality ensured by a highly specialized production process at LANXESS. The nanoparticles with the swell-resistant, highly cross-linked core have special "anchor points" on their surface, enabling the Nanoprene particles to be perfectly linked with silica and silanes. Silica is deployed in modern tires instead of carbon black to cut rolling resistance and gives tires excellent wet grip. "Adding Nanoprene to a tread mix containing silica improves wear resistance and grip. At the same time, rolling resistance remains at a low level. The "magic triangle" is therefore extended," says Prof. Obrecht, highlighting the physical and chemical relationships.

The use of Nanoprene does not entail disadvantages on the process engineering side. Tire manufacturers can, unlike with most "traditional" additives, retain their tried and tested rubber formulations and yet significantly cut wear caused by abrasion. "Nanoprene may be viewed very much as a sort of spice that makes a good recipe even better," says Obrecht. Even the form in which the new product is supplied will be familiar to users. The additive produced by LANXESS at the emulsion rubber production plant in La Wantzenau, France, arrives at the customer in bale form as with any tire rubber. All that has to be done is to optimize the sequence and timing for adding additives and to adapt to the mixing equipment used to enable Nanoprene to deliver the optimal effect. Users can request support for this from LANXESS.

The first products with this additive are already on the market. Nanoprene is currently undergoing extensive tests at selected tire manufacturers. The Nanoprene product range will be expanded in the near future with further grades that vary, for example, in terms of their glass transition temperature - i.e. their low-temperature flexibility - and are thus even better suited to specific types of tire. "With Nanoprene, we haven't just succeeded in making a specialty product out of ordinary SBR tire rubber," explains Obrecht. "This innovation sees us living up to our reputation as a premium supplier and technology leader in the industry."

Together with LANXESS's Rhein Chemie business unit, TRP is opening up further application areas for Nanoprene. These include impact resistance modification for thermoplastics and thermosetting plastics. Work is also under way to develop a specific Nanoprene grade for fuel cell membranes. LANXESS has created numerous patents during the development of Nanoprene which are already applied for patent protection worldwide.

####

About LANXESS

LANXESS is a leading specialty chemical company, with sales of EUR 6.94 billion in 2006 and some 14,500 employees in 21 countries around the world. The company has operations at 47 sites worldwide. LANXESS’s core business comprises the development, manufacture and sale of specialty chemicals, plastics, rubber and intermediates.

Forward-Looking Statements

This news release contains forward-looking statements based on current assumptions and forecasts made by LANXESS AG management. Various known and unknown risks, uncertainties and other factors could lead to material differences between the actual future results, financial situation, development or performance of the company and the estimates given here. The company assumes no liability whatsoever to update these forward-looking statements or to conform them to future events or developments.

For more information, please click here

Contacts:

Michael Fahrig

Tel.: +49 214 30 45041

Fax.: +49 214 30 44865

Copyright © LANXESS

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related News Press |

News and information

![]() Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Products

![]() Spectradyne Partners with Particle Technology Labs for Measurement Services December 6th, 2018

Spectradyne Partners with Particle Technology Labs for Measurement Services December 6th, 2018

![]() Mode-Changing MEMS Accelerometer from STMicroelectronics Combines High Measurement Resolution and Ultra-Low Power for Industrial Applications November 7th, 2018

Mode-Changing MEMS Accelerometer from STMicroelectronics Combines High Measurement Resolution and Ultra-Low Power for Industrial Applications November 7th, 2018

![]() Fat-Repellent Nanolayers Can Make Oven Cleaning Easier October 17th, 2018

Fat-Repellent Nanolayers Can Make Oven Cleaning Easier October 17th, 2018

![]() Aculon, Inc. Enters into Strategic Partnership Agreement with Henkel Corporation to Supply Key Mobile Device Manufacturers with NanoProof® PCB Waterproof Technology October 17th, 2018

Aculon, Inc. Enters into Strategic Partnership Agreement with Henkel Corporation to Supply Key Mobile Device Manufacturers with NanoProof® PCB Waterproof Technology October 17th, 2018

Materials/Metamaterials/Magnetoresistance

![]() Nanoscale CL thermometry with lanthanide-doped heavy-metal oxide in TEM March 8th, 2024

Nanoscale CL thermometry with lanthanide-doped heavy-metal oxide in TEM March 8th, 2024

![]() Focused ion beam technology: A single tool for a wide range of applications January 12th, 2024

Focused ion beam technology: A single tool for a wide range of applications January 12th, 2024

Announcements

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Automotive/Transportation

![]() Researchers’ approach may protect quantum computers from attacks March 8th, 2024

Researchers’ approach may protect quantum computers from attacks March 8th, 2024

![]() Tests find no free-standing nanotubes released from tire tread wear September 8th, 2023

Tests find no free-standing nanotubes released from tire tread wear September 8th, 2023

Fuel Cells

![]() Current and Future Developments in Nanomaterials and Carbon Nanotubes: Applications of Nanomaterials in Energy Storage and Electronics October 28th, 2022

Current and Future Developments in Nanomaterials and Carbon Nanotubes: Applications of Nanomaterials in Energy Storage and Electronics October 28th, 2022

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||