Home > Press > Nano-layer of Ruthenium Stabilizes Magnetic Sensors

|

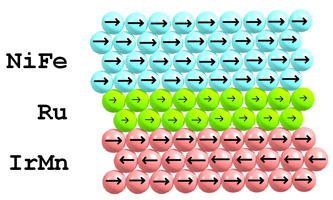

| A thin layer of ruthenium (green in the cartoon) improves magnetic sensors by modulating interactions between a nickel/iron film (blue) that responds to external magnetic fields and an iridium/manganese stabilizer film (pink). The ruthenium aligns its electron spins, indicated by arrows, with the nearest layers in both films.

Credit: NIST |

Abstract:

A layer of ruthenium just a few atoms thick can be used to fine-tune the sensitivity and enhance the reliability of magnetic sensors, tests at the National Institute of Standards and Technology (NIST) show.* The nonmagnetic metal acts as a buffer between active layers of sensor materials, offering a simple means of customizing field instruments such as compasses, and stabilizing the magnetization in a given direction in devices such as computer hard-disk readers.

Nano-layer of Ruthenium Stabilizes Magnetic Sensors

GAITHERSBURG, MD | Posted on August 3rd, 2007n the NIST sensor design, ruthenium modulates interactions between a ferromagnetic film (in which electron "spins" all point in the same direction) and an antiferromagnetic film (in which different layers of electrons point in opposite directions to stabilize the device). In the presence of a magnetic field, the electron spins in the ferromagnetic film rotate, changing the sensor's resistance and producing a voltage output. The antiferromagnetic film, which feels no force because it has no net magnetization, acts like a very stiff spring that resists the rotation and stabilizes the sensor. The ruthenium layer (see graphic) is added to weaken the spring, effectively making the device more sensitive. This makes it easier to rotate the electron spins, and still pulls them back to their original direction when the field is removed.

NIST tests showed that thicker buffers of ruthenium (up to 2 nanometers) make it easier to rotate the magnetization of the ferromagnetic film, resulting in a more sensitive device. Thinner buffers result in a device that is less sensitive but responds to a wider range of external fields. Ruthenium layers thicker than 2 nm prevent any coupling between the two active films. All buffer thicknesses from 0 to 2 nm maintain sensor magnetization (even resetting it if necessary) without a boost from an external electrical current or magnetic field. This easily prevents demagnetization and failure of a sensor.

The mass-producible test sensors, made in the NIST clean room in Boulder, Colo., consist of three basic layers of material deposited on silicon wafers: The bottom antiferromagnetic layer is 8 nm of an iridium/manganese alloy, followed by the ruthenium buffer, and topped with 25 nm of a nickel/iron alloy. The design requires no extra lithography steps for the magnetic layers and could be implemented in existing mass-production processes. By contrast, the conventional method of modulating magnetoresistive sensors—capping the ends of sensors with magnetic materials—adds fabrication steps and does not allow fine-tuning of sensitivity. The new sensor design was key to NIST's recent development of a high-resolution forensic tape analysis system for the Federal Bureau of Investigation (see Magnetic Tape Analysis "Sees" Tampering in Detail).

http://www.nist.gov/public_affairs/techbeat/tb2007_0720.htm#tape

* S.T. Halloran, F.C. da Silva, H.Z. Fardi and D.P. Pappas. Permanent-magnet-free stabilization and sensitivity tailoring of magneto-resistive field sensors, Journal of Applied Physics. August 1, 2007.

####

About NIST

Founded in 1901, NIST is a non-regulatory federal agency within the U.S. Commerce Department's Technology Administration. NIST's mission is to promote U.S. innovation and industrial competitiveness by advancing measurement science, standards, and technology in ways that enhance economic security and improve our quality of life.

For more information, please click here

Contacts:

Laura Ost

(303) 497-4880

Copyright © NIST

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related News Press |

Sensors

Announcements

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||