Home > Press > Laser Micromachining centre offers unique opportunity for businesses

|

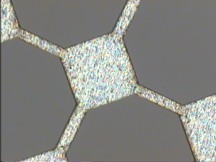

| Laser machined 0.025mm thick stainless steel foil showing 0.08mm wide struts |

Abstract:

A one-hour awareness-raising breakfast meeting is a unique and free opportunity for businesses looking for engineering solutions.

Laser Micromachining centre offers unique opportunity for businesses

UK | Posted on June 23rd, 2007The wide-ranging benefits of laser micromachining make it an especially effective tool for product development and prototyping stages of production. Design imagination coupled with laser micromachining flexibility ensure new ideas and concepts can be rapidly evaluated. Companies that seize the opportunity to use the latest technology will be those that retain and improve their market share increasing pressure on businesses to adopt and exploit the very latest small-scale engineering techniques. The challenge, of course, is how to achieve this within existing resources. Not every venture has the technology expertise in-house; few organizations have the resources to research, develop and then prototype new products before committing to volume production.

Often many versions of parts can be made within a single day reducing laborious design stages and allowing product refinements to be made cost-effectively. Companies refining existing product designs to provide extended technical capabilities have found these features of laser micromachining particularly useful. A practical example of how laser micromachining can improve manufacturing is a filter product which contains a thin metal foil with a mesh of 0.5mm wide struts (pictured above).

Laser micromachining is regarded as the new manufacturing method that can not only produce the new design but can also streamline the assembly process. Since laser micromachining is a non-contact process, the metal foil could be pre-mounted in its holder before the mesh was machined in situ. This improved not only the product specification but also the production yield since no handling of the delicate foil was required after it had been machined. This process development route typifies the benefits which the uses of laser processing brings to manufacturing problems.

Dr. Nadeem Rizvi of the UK Laser Micromachining Centre will present on the business opportunities that laser micromachining can offer in product development and manufacture. Dr. Rizvi will focus on the benefits of laser micromachining for various applications. The characteristics of the main types of lasers which are used for producing micro and nano scale features will be highlighted. The talk will provide examples (including videos) of high precision laser micromachining and offer a view on upcoming developments. A brief practical guide will be provided to some of the major issues in laser micromachining: laser ablation; optics and processing methods; materials issues; processing parameters.

This free event will take place in Cardiff on July 4, 2007, and will precede a one-day workshop on ‘Laser Microprocessing of Challenging Materials and Architectures' which attendees may stay on to participate in. The meeting is supported by the Welsh Assembly Government's Knowledge Exploitation Fund to promote the training and life long learning available from the MNT Academy.

metaFAB - MNT Academy Breakfast

Exploiting Laser Micromachining in Advanced Manufacturing

Free of Charge

metaFAB Xtreme Laser Facility, Cardiff University July 4th 2007

Breakfast served from 08.00 Seminar 08.45 - 09.45

####

About UK Laser Micromachining Centre

The UK Laser Micromachining Centre is part of the XGEN enterprise which has been established as a one-stop-shop resource to take businesses into the next generation. If you’re looking to stay ahead of your competitors and find out how your business can benefit make sure you don’t miss this insight into laser micromachining.

For more information, please click here

Contacts:

Richard Bahu

MNT Academy Manager

T: 07802 201708

Copyright © UK Laser Micromachining Centre

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related News Press |

Announcements

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Events/Classes

![]() Researchers demonstrate co-propagation of quantum and classical signals: Study shows that quantum encryption can be implemented in existing fiber networks January 20th, 2023

Researchers demonstrate co-propagation of quantum and classical signals: Study shows that quantum encryption can be implemented in existing fiber networks January 20th, 2023

Photonics/Optics/Lasers

![]() With VECSELs towards the quantum internet Fraunhofer: IAF achieves record output power with VECSEL for quantum frequency converters April 5th, 2024

With VECSELs towards the quantum internet Fraunhofer: IAF achieves record output power with VECSEL for quantum frequency converters April 5th, 2024

![]() Nanoscale CL thermometry with lanthanide-doped heavy-metal oxide in TEM March 8th, 2024

Nanoscale CL thermometry with lanthanide-doped heavy-metal oxide in TEM March 8th, 2024

![]() Optically trapped quantum droplets of light can bind together to form macroscopic complexes March 8th, 2024

Optically trapped quantum droplets of light can bind together to form macroscopic complexes March 8th, 2024

![]() HKUST researchers develop new integration technique for efficient coupling of III-V and silicon February 16th, 2024

HKUST researchers develop new integration technique for efficient coupling of III-V and silicon February 16th, 2024

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||