Home > Press > Adding nanotubes makes ordinary materials absorb vibration

Abstract:

New composites could remove buzz from speakers, sting from golf clubs

Adding nanotubes makes ordinary materials absorb vibration

Troy, NY | Posted on February 08, 2006

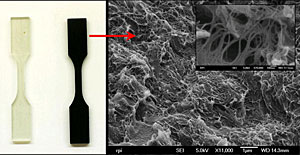

A new study suggests that integrating nanotubes into traditional materials dramatically improves their ability to reduce vibration, especially at high temperatures. The findings could pave the way for a new class of materials with a multitude of applications, from high-performance parts for spacecraft and automobile engines, to golf clubs that don’t sting and stereo speakers that don’t buzz.

The materials, developed by researchers at Rensselaer Polytechnic Institute, are described in the Feb. 8 issue of the journal Nano Letters.

Nanocomposites don’t suffer from the same weight and volume penalties as current polymeric damping materials, but the new findings point to another important advantage, according to Nikhil Koratkar, associate professor of mechanical, aerospace, and nuclear engineering at Rensselaer and lead author of the paper. “Traditional damping polymers perform poorly at elevated temperatures,” he says. “Our new materials provide excellent damping at high temperatures, suggesting that these nanocomposites show great potential for a variety of applications in aircraft, spacecraft, satellites, automobiles, and even sensors for missile systems — basically any structure that is exposed to vibration.”

Though much of the research focus has been on improving the strength and stiffness of nanomaterials, Koratkar and his coworkers have directed their attention to another important property: damping, or the ability of a material to dissipate energy. They have found that dispersing nanotubes throughout traditional materials creates new composites with vastly improved damping capabilities. And they have also shown for the first time that these damping properties are enhanced as the temperature increases.

Carbon nanotubes are made from graphite-like carbon, where the atoms are arranged like a rolled-up tube of chicken wire. They have enticed researchers since their discovery in 1991, offering an impressive combination of high strength and low weight, but few commercial applications have resulted in the intervening years, according to Koratkar.

The new materials could be extremely useful for any kind of space application, because temperatures swing wildly from very hot in the day to very cold at night, Koratkar notes. And he expects to use them in the diaphragms of loud speakers to help improve sound quality by reducing the buzz associated with high bass levels.

The sporting goods market is also an especially promising outlet, particularly for golf clubs and tennis racquets. “Manufacturers want tennis racquets and golf club shafts to be light and stiff, but without the annoying sting that comes from a bad shot,” Koratkar says.

Pulickel Ajayan, the Henry Burlage Professor of Materials Science and Engineering at Rensselaer and a world-renowned expert in fabricating nanotube materials, collaborated with Koratkar on this project, and two other Rensselaer researchers were involved with the research: Jonghwan Suhr, a post-doctoral researcher in mechanical, aerospace, and nuclear engineering; and Wei Zhang, a graduate student in aeronautical engineering.

In 2004, Koratkar received a National Science Foundation Faculty Early Career Development Award to fund the development of these new materials. Additional funding for this project was provided by the U.S. Army Research Office.

Nanotechnology at Rensselaer:

In September 2001, the National Science Foundation selected Rensselaer as one of the six original sites for a new Nanoscale Science and Engineering Center (NSEC). As part of the U.S. National Nanotechnology Initiative, the program is housed within the Rensselaer Nanotechnology Center and forms a partnership between Rensselaer, the University of Illinois at Urbana-Champaign, and Los Alamos National Laboratory. The mission of Rensselaer’s Center for Directed Assembly of Nanostructures is to integrate research, education, and technology dissemination, and to serve as a national resource for fundamental knowledge in directed assembly of nanostructures. The five other original NSECs are located at Harvard University, Columbia University, Cornell University, Northwestern University, and Rice University.

About Rensselaer:

Rensselaer Polytechnic Institute, founded in 1824, is the nation’s oldest technological university. The university offers bachelor’s, master’s, and doctoral degrees in engineering, the sciences, information technology, architecture, management, and the humanities and social sciences. Institute programs serve undergraduates, graduate students, and working professionals around the world. Rensselaer faculty are known for pre-eminence in research conducted in a wide range of fields, with particular emphasis in biotechnology, nanotechnology, information technology, and the media arts and technology. The Institute is well known for its success in the transfer of technology from the laboratory to the marketplace so that new discoveries and inventions benefit human life, protect the environment, and strengthen economic development.

For more information, please click here.

Contact:Jason Gorss

Office of Communications

Rensselaer Polytechnic Institute

phone: 518-276-6098

fax: 518-276-6091

gorssj@rpi.edu

news.rpi.edu/

Copyright © Rensselaer Polytechnic Institute

If you have a comment, please Contact us.

Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related News Press |

Products

![]() Spectradyne Partners with Particle Technology Labs for Measurement Services December 6th, 2018

Spectradyne Partners with Particle Technology Labs for Measurement Services December 6th, 2018

![]() Mode-Changing MEMS Accelerometer from STMicroelectronics Combines High Measurement Resolution and Ultra-Low Power for Industrial Applications November 7th, 2018

Mode-Changing MEMS Accelerometer from STMicroelectronics Combines High Measurement Resolution and Ultra-Low Power for Industrial Applications November 7th, 2018

![]() Fat-Repellent Nanolayers Can Make Oven Cleaning Easier October 17th, 2018

Fat-Repellent Nanolayers Can Make Oven Cleaning Easier October 17th, 2018

![]() Aculon, Inc. Enters into Strategic Partnership Agreement with Henkel Corporation to Supply Key Mobile Device Manufacturers with NanoProof® PCB Waterproof Technology October 17th, 2018

Aculon, Inc. Enters into Strategic Partnership Agreement with Henkel Corporation to Supply Key Mobile Device Manufacturers with NanoProof® PCB Waterproof Technology October 17th, 2018

Possible Futures

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

![]() With VECSELs towards the quantum internet Fraunhofer: IAF achieves record output power with VECSEL for quantum frequency converters April 5th, 2024

With VECSELs towards the quantum internet Fraunhofer: IAF achieves record output power with VECSEL for quantum frequency converters April 5th, 2024

Nanotubes/Buckyballs/Fullerenes/Nanorods/Nanostrings

![]() Tests find no free-standing nanotubes released from tire tread wear September 8th, 2023

Tests find no free-standing nanotubes released from tire tread wear September 8th, 2023

![]() Detection of bacteria and viruses with fluorescent nanotubes July 21st, 2023

Detection of bacteria and viruses with fluorescent nanotubes July 21st, 2023

Materials/Metamaterials/Magnetoresistance

![]() Nanoscale CL thermometry with lanthanide-doped heavy-metal oxide in TEM March 8th, 2024

Nanoscale CL thermometry with lanthanide-doped heavy-metal oxide in TEM March 8th, 2024

![]() Focused ion beam technology: A single tool for a wide range of applications January 12th, 2024

Focused ion beam technology: A single tool for a wide range of applications January 12th, 2024

Announcements

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Sports

![]() Surrey reveals its implantable biosensor that operates without batteries May 22nd, 2020

Surrey reveals its implantable biosensor that operates without batteries May 22nd, 2020

![]() Collagen nanofibrils in mammalian tissues get stronger with exercise December 14th, 2018

Collagen nanofibrils in mammalian tissues get stronger with exercise December 14th, 2018

![]() Epoxy compound gets a graphene bump: Rice scientists combine graphene foam, epoxy into tough, conductive composite November 14th, 2018

Epoxy compound gets a graphene bump: Rice scientists combine graphene foam, epoxy into tough, conductive composite November 14th, 2018

Aerospace/Space

![]() Under pressure - space exploration in our time: Advancing space exploration through diverse collaborations and ethical policies February 16th, 2024

Under pressure - space exploration in our time: Advancing space exploration through diverse collaborations and ethical policies February 16th, 2024

![]() Bridging light and electrons January 12th, 2024

Bridging light and electrons January 12th, 2024

![]() Manufacturing advances bring material back in vogue January 20th, 2023

Manufacturing advances bring material back in vogue January 20th, 2023

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||