Home > Nanotechnology Columns > NanoGlobe > Almost No Cost Generation of Catalyst Patterns for Growth of Large-Scale Densely Aligned SWCNTs

|

NanoGlobe Pte Ltd Nanotechnology Business Development Consultants NanoGlobe Pte Ltd |

Abstract:

Single-walled carbon nanotubes (SWCNTs) are very important especially in electronics miniaturization due to their excellent electric properties different from the multi-walled carbon nanotubes (MWCNTs) variants. CNT can be synthesized via many techniques including arc discharge, laser ablation, and chemical vapor deposition (CVD). Among the various methods, CVD shows to be the most promising method for industrial-scale deposition, because of its price-per-unit ratio and it is capable of growing nanotubes directly on a desired substrate. However, the growth sites must be controlled by a careful deposition of the catalyst involved. In this article, we report a simple novel method to generate the catalyst pattern for growing high quality SWCNTs with very low cost, opening up another possibility to commercial scale applications of SWCNTs.

June 27th, 2009

Almost No Cost Generation of Catalyst Patterns for Growth of Large-Scale Densely Aligned SWCNTs

A research group at the School of Materials Science & Engineering, Nanyang Technological University (NTU), Singapore, led by Assistant Prof. Hua Zhang has come up with an extremely simple, fast, almost no cost and environmentally friendly technique called "Needle-Scratching" Method (NSM) to generate catalyst patterns used for growing large-scale densely aligned single-walled carbon nanotubes (SWCNTs) arrays as recently published online in Small, http://dx.doi.org/10.1002/smll.200900654 .

|

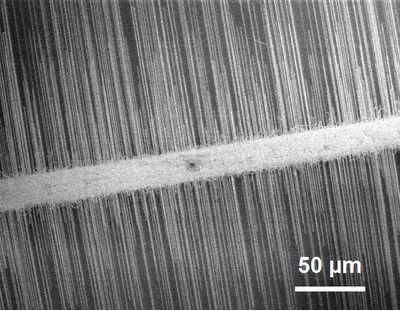

| An SEM image of densely aligned SWCNT arrays grown from the NSM-generated catalyst stripe on quartz substrate (source: Asst/P Hua Zhang, MSE-NTU) |

NSM is a technique to produce uniform and high-density catalyst nanoparticles by simply scratching the substrate with the sharp tip of a common syringe needle. The high density of SWCNTs can then grow from the catalyst patterns after consequent chemical vapor deposition (CVD). Started with Si/SiOx substrate, Zhang and his team have demonstrated the growth of densely aligned SWCNT arrays on quartz substrates with controlled pattern location, spacing and direction by NSM with a micro-manipulator. The aligned SWCNT arrays successfully grew from the scratched areas with the density as high as 10 tubes Ám-1 and length up to 0.5 mm.

NSM has overcome various limitations found in the traditional lithography methods (e.g. photolithography, e-beam lithography, micro-contact printing) used to prepare catalyst patterns. Catalyst patterns generation is a crucial step in growing high density and well aligned SWCNTs, which is an ideal material for constructing high performance thin film transistors due to its multiple transport pathways and absence of tube-tube overlapping junction problems.

Furthermore, the process can be readily scaled up by using multiple needle arrays. NSM provides a very convenient route to produce high density, high quality SWCNT arrays that may create great impact on further study of their applications as well as the fabrication of CNT-based nanodevices (source: Asst/P Hua Zhang, MSE-NTU).

(Yesie Brama, Technology Analyst, NanoGlobe Pte Ltd)

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||